Makina ojambulira mabotolo odziyimira pawokha

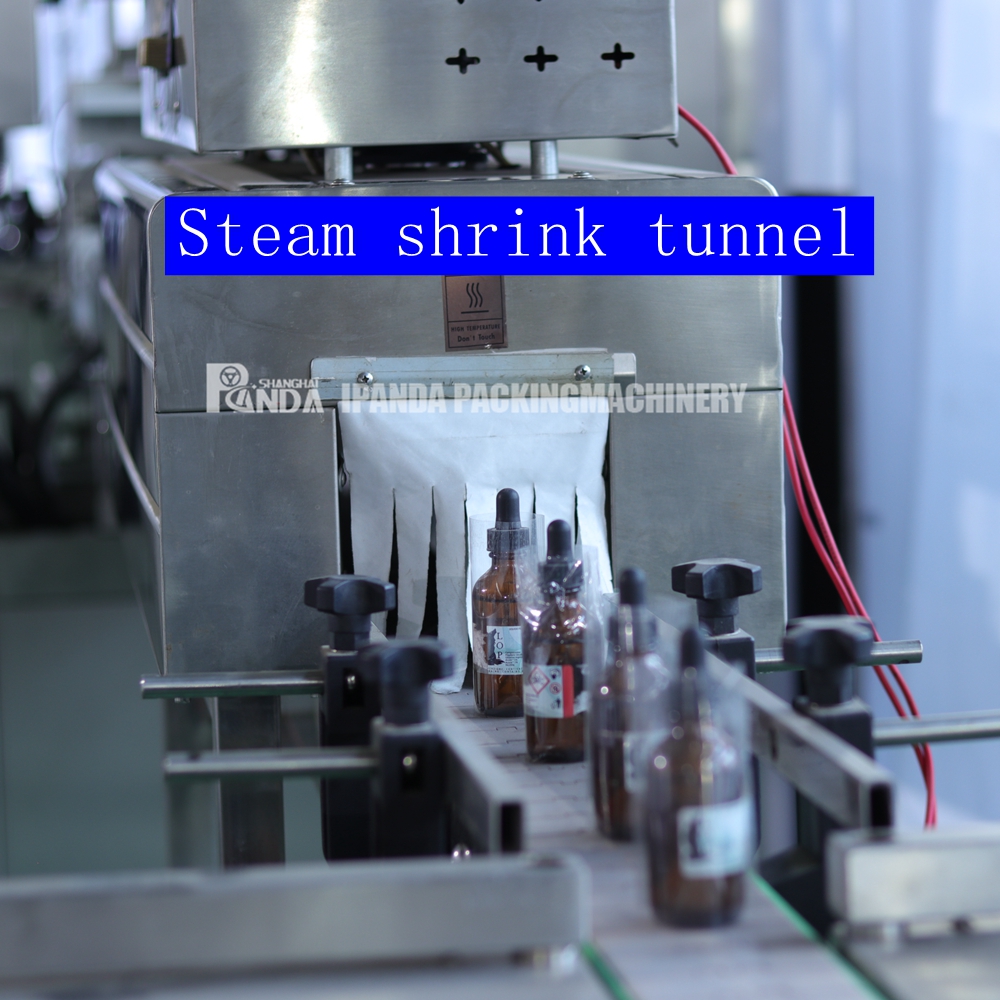

Makinawa amatenga ukadaulo wapamwamba wapadziko lonse lapansi;kuphimba chizindikiro chozungulira pa botolo la pet.Ndiyeno kutentha kucheperachepera kuti akonze malo omwe thupi la botolo lidasankha.Mapangidwe a makinawa ndi ophatikizana, komanso oyenera kupanga mzere wosiyana ndi kutalika kosiyana.

Gawo lamakina limagwiritsa ntchito mapangidwe ophatikizika a modularization, ndikupanga makinawo kukhala oyenera.Kusintha kutalika kutengera kusinthasintha kwagalimoto;ndikosavuta kusintha zinthuzo.Kujambula kwapadera kwa mutu wa cutter, kupanga filimuyo kudulidwa kudulidwa ndendende komanso modalirika.

| Dameter ya mabotolo oyenera | 20-125 mm |

| Kutalika kwa Botolo | 15-320 mm |

| Kukula kwa zilembo (L*H) | 50-330-40-150 mm |

| Oyenera mawonekedwe a botolo | zozungulira, masikweya, elliptical, amakona anayi |

| Mtengo wolembera | ≥99.9% |

| Label kutalika | 25-200 mm |

| Label Makulidwe | 0.035-0.08mm |

| Lembani pakati pa pepala lalikulu | 3-10 mm |

| Voltage & Mphamvu | 220V, 2KW |

| Kalemeredwe kake konse | 500KG |

1. Zonse zotsekedwa Thupi lalikulu lachitsulo chosapanga dzimbiri: Chitetezo kwa wogwiritsa ntchito.Makina onsewa ndi osatetezedwa ndi madzi komanso odana ndi dzimbiri.

2. Phala la mpeni wosinthika: Mpeni wamtundu wozungulira wopangidwa mwapadera, wamitundu iwiri wokhala ndi nthawi yayitali.

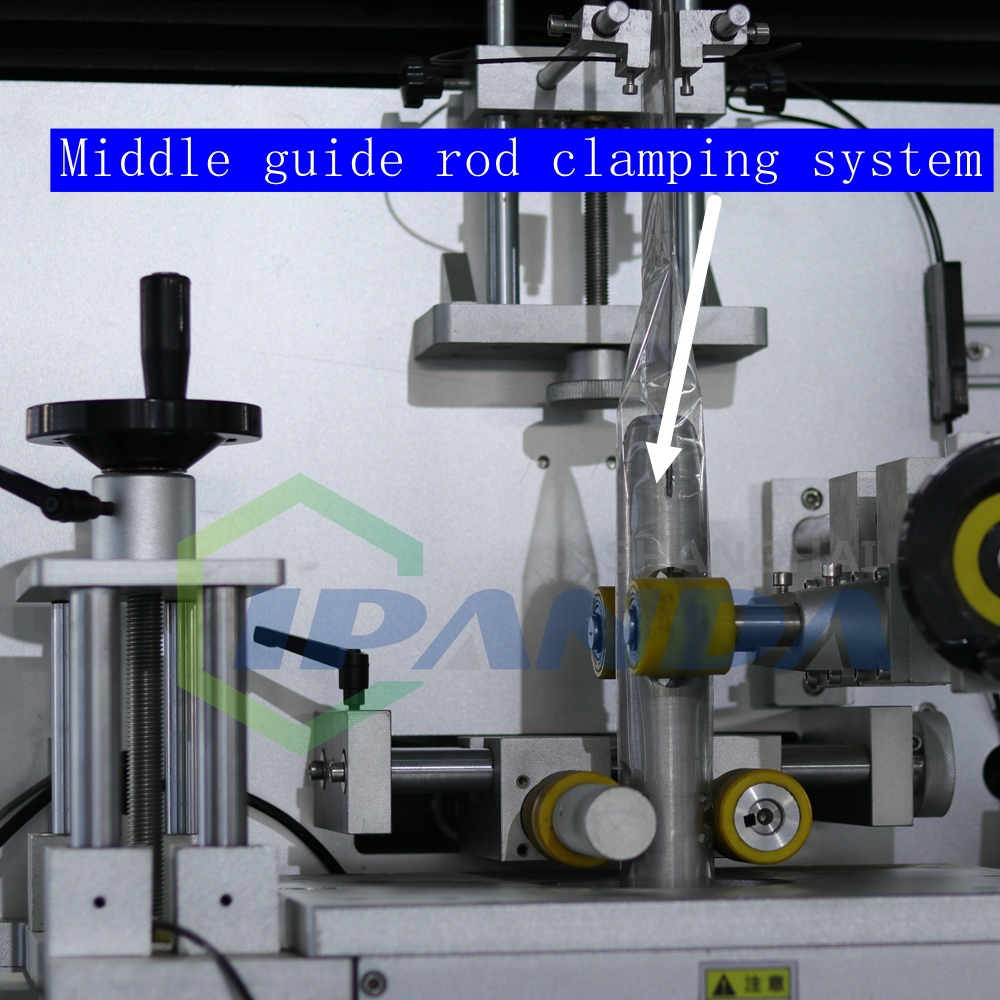

3. Mzere wapakatikati pa malo amodzi: perekani chizindikirocho mokhazikika

4. Kusintha kwa Malo a Botolo: botolo silidzatha ndi conveyor ndikuyenda mokhazikika

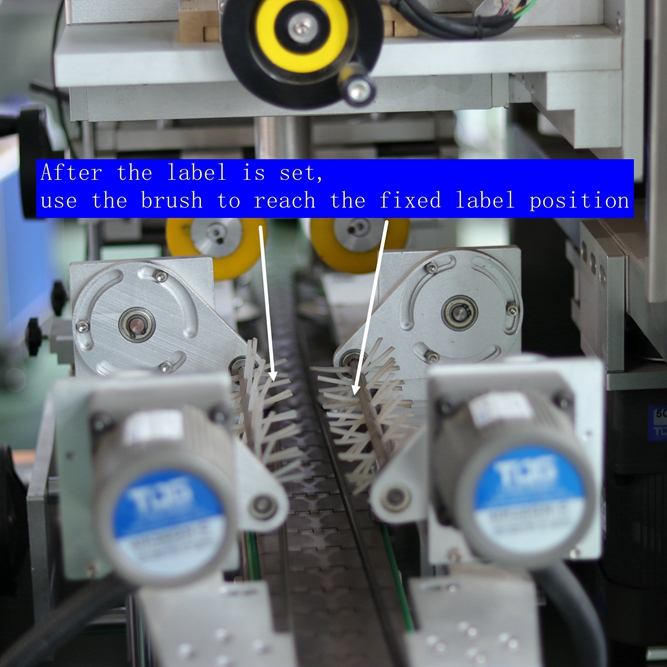

5. Burashi kuti muyike zilembo: Zolondola kwambiri.

6. Label control photocell frame: Wapadera empennage pamodzi ndi photocell, kumapangitsanso kudula molondola.

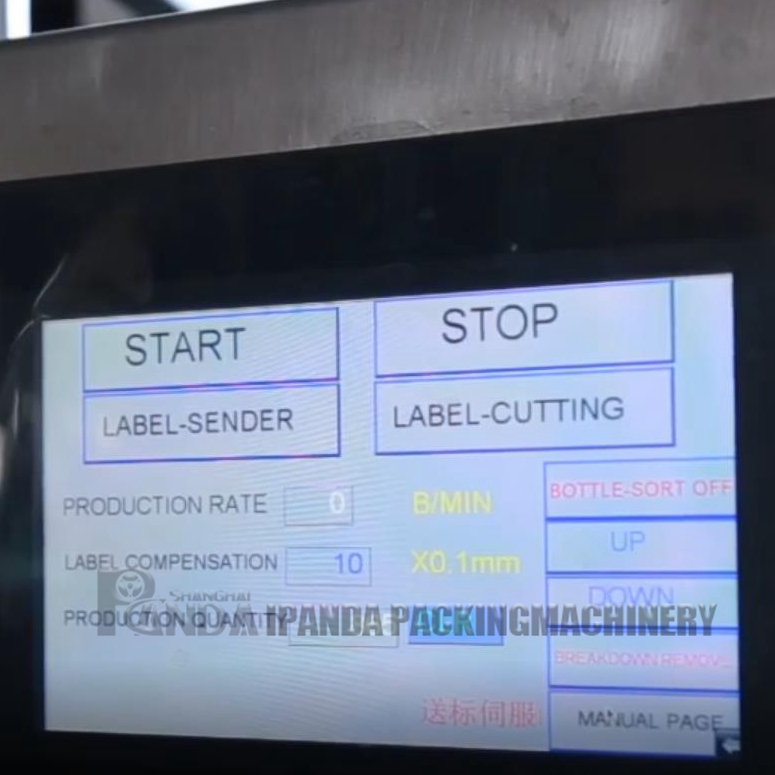

7. Chojambula cha HMI chamtundu umodzi

8. Anakonza ndi kudyetsa chimango Bar

1. Mzere wonsewo ukhoza kusinthidwa kupanga zokha kapena pamanja: Kuwongolera liwiro lodziwikiratu: mawonekedwe odziwikiratu pamakina athu amatha kusinthidwa molingana ndi njira yakale yopangira liwiro lokha, ndi mabotolo amaso amatsenga, makina otsatizana odziwikiratu omwe ali ndi ntchito yabwino komanso yachangu automation Manual control: ikhoza kukhala molingana ndi zofunikira za liwiro la kupanga kuwongolera ndandanda yoperekera, kuthamanga kwa liwiro laumunthu kwathunthu.

2. Kusokonekera kwa makina onse kumangodziwikiratu, gwirizanani ndi mawonekedwe a makina amunthu pamawonekedwe achi China ndi alamu ya trichromatic nyali, fufuzani panthawi yake zifukwa zolephera zida

3. Kutumiza kwa makina a seti yathunthu ya ma synchronous transmission amayenera kusintha kapu, mutha kusintha mosavuta makina othamanga.Makinawa amazindikira okha kusintha liwiro lodziwikiratu.

4. Single positioning kalozera mzati mtundu pakati: okhazikika kwambiri kutsogolera chizindikiro.

5. Mutu wodula wosinthika: choyambirira cha cyclotron chodulidwa, masamba awiri, moyo wautali;

6. Mtundu wa botolo wogwiritsidwa ntchito: mabwalo ozungulira, ophwanyika, mtundu wa chikho ndi mabotolo amtundu wa curve wosakhazikika.

Mwatsatanetsatane chithunzi:

Ma shelefu amagetsi owongolera ma label: kuphatikiza kwapadera kwa mchira ndi diso lamagetsi kuti muwongolere kulondola kwa kudula zida za membrane.

Mutu wodula wosinthika:

mosakayikira cyclotron kudula, mbali ziwiri zodula ndi moyo wautali wautumiki.

Single postioning center kalozera mzati:okhazikika popereka zilembo.