Botolo la Katemera Wodzaza Botolo Loyimitsa Kuyimitsa

Mzere wopangira kudzaza vial umapangidwa ndi makina ochapira akupanga mabotolo, chowumitsira chowumitsa, makina oyimitsa, ndi makina ojambulira.Itha kumaliza kupopera madzi, kuyeretsa kwa akupanga, kutulutsa khoma lamkati ndi lakunja la botolo, kutentha, kuyanika ndi kutseketsa, kuchotsa gwero la kutentha, kuziziritsa, kutulutsa botolo, (nitrogen pre-filling), kudzaza, (nitrogen post-filling), choyimitsa. kusagwetsa, kukanikiza koyimitsa, kutsekereza kapu, kutsekereza ndi ntchito zina zovuta, kuzindikira kupanga zokha zonsezo.Makina aliwonse amatha kugwiritsidwa ntchito padera, kapena pamzere wolumikizira.Mzere wonsewo umagwiritsidwa ntchito podzaza jakisoni wamadzimadzi a vial ndi jakisoni wa ufa wowumitsidwa m'mafakitole opanga mankhwala, utha kugwiritsidwanso ntchito popanga maantibayotiki, mankhwala a bio-pharmaceuticals, mankhwala opangira mankhwala, mankhwala amagazi ndi zina.

| Chitsanzo | Chithunzi cha SHPD4 | Chithunzi cha SHPD6 | Chithunzi cha SHPD8 | Mtengo wa SHPD10 | Mtengo wa SHPD12 | Mtengo wa SHPD20 | Chithunzi cha SHPD24 |

| Zoyenera kuchita | 2 ~ 30ml mabotolo a vial | ||||||

| Kudzaza mitu | 4 | 6 | 8 | 10 | 12 | 20 | 24 |

| Mphamvu zopanga | 50-100bts/mphindi | 80-150bts/mphindi | 100-200bts/mphindi | 150-300bts/mphindi | 200-400bts/mphindi | 250-500bts/mphindi | 300-600bts/mphindi |

| Kuyimitsa qualification rate | =99% | ||||||

| Laminar mpweya ukhondo | 100 kalasi | ||||||

| Kuthamanga kwa vacuum | 10m3/h | 30m3/h | 50m3/h | 60m3/h | 60m3/h | 100m3/h | 120m3/h |

| Kugwiritsa ntchito mphamvu | 5 kw | ||||||

| Magetsi | 220V/380V 50Hz | ||||||

1.Itha kukhala ndi chivundikiro choteteza komanso choyikapo chotsitsa malinga ndi zomwe kasitomala akufuna.

2.Ili ndi ubwino wa digiri yapamwamba yodzipangira okha, yapamwamba kwambiri ya zinthu zomalizidwa, kusinthasintha kwabwino komanso kukhazikika komwe kumatchuka pakati pa ogwiritsa ntchito.

3. Imatengera pulogalamu ya PLC yoyang'anira, yokhala ndi makina ogwiritsira ntchito makina ogwiritsira ntchito makina, ndi yabwino komanso yosavuta kugwiritsa ntchito.

4.Makina odzaza amapangidwa molingana ndi zofunikira za GMP, zomwe zimapangidwa ndi chitsulo chosapanga dzimbiri pansi pa mayiko a SUS316L, SUS304.

Botolo lowuma lomwe likubwera (losawilitsidwa ndi siliconised) limadyetsedwa kudzera mu chosakanizira ndikuwongoleredwa moyenera pa lamba wosuntha wa delrin slat pa liwiro loyenera la kuyika kolondola pansipa.Chigawo chodzazacho chimakhala ndi Kudzaza Mutu, Masyringe & Nozzles omwe amagwiritsidwa ntchito podzaza madzi.Ma syringe amapangidwa ndi SS 316 yomanga ndipo onse, magalasi komanso ma syringe a SS angagwiritsidwe ntchito.Wheel ya Star imaperekedwa yomwe imakhala ndi vial panthawi yodzaza.Sensa imaperekedwa.

1) Uku ndikudzaza mapaipi, ndi mapaipi apamwamba kwambiri ochokera kunja. Pali ma valve pa chitoliro, imayamwa madzi pambuyo podzaza kamodzi.Kotero kudzaza nozzles sikungatayike.

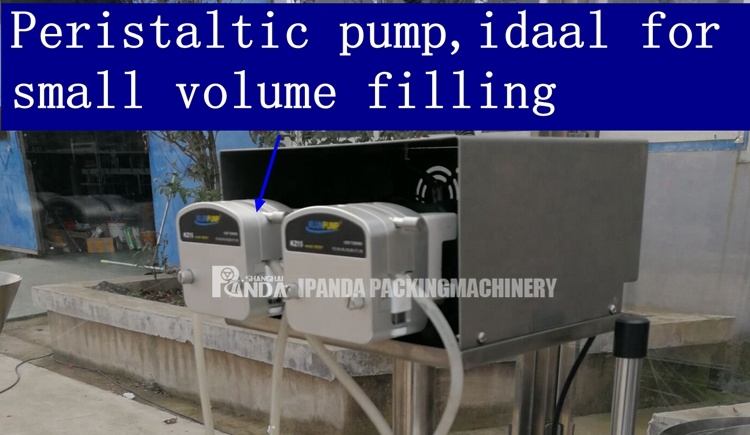

2) Maonekedwe odzigudubuza ambiri a pampu yathu ya peristaltic imapangitsanso kukhazikika komanso kusakhudzika kwa kudzaza ndikupanga kudzaza kwamadzimadzi kukhala kokhazikika komanso kosavuta kutulutsa.Ndizoyenera makamaka kudzaza madziwa ndi chofunika kwambiri.

3) Ichi ndi aluminium Cap yosindikiza mutu.Ili ndi ma roller atatu osindikizira.Idzasindikiza Cap kuchokera kumbali zinayi, kotero Cap yosindikizidwa imakhala yolimba kwambiri komanso yokongola.Sichidzawononga Cap kapena kutayikira Cap.

1.Tikhoza kupereka mapangidwe a OEC / ODM.

2.Timapereka chitsimikizo cha chaka cha 1 ndi zida zopangira zaulere (osati zopangidwa ndi anthu), tidzakonzekeranso zida zokwanira zoperekedwa

pamodzi ndi makina.

3.Makina athu adapangidwa mwadongosolo losavuta, kotero kuti ndizosavuta kugwiritsa ntchito komanso kuwongolera.

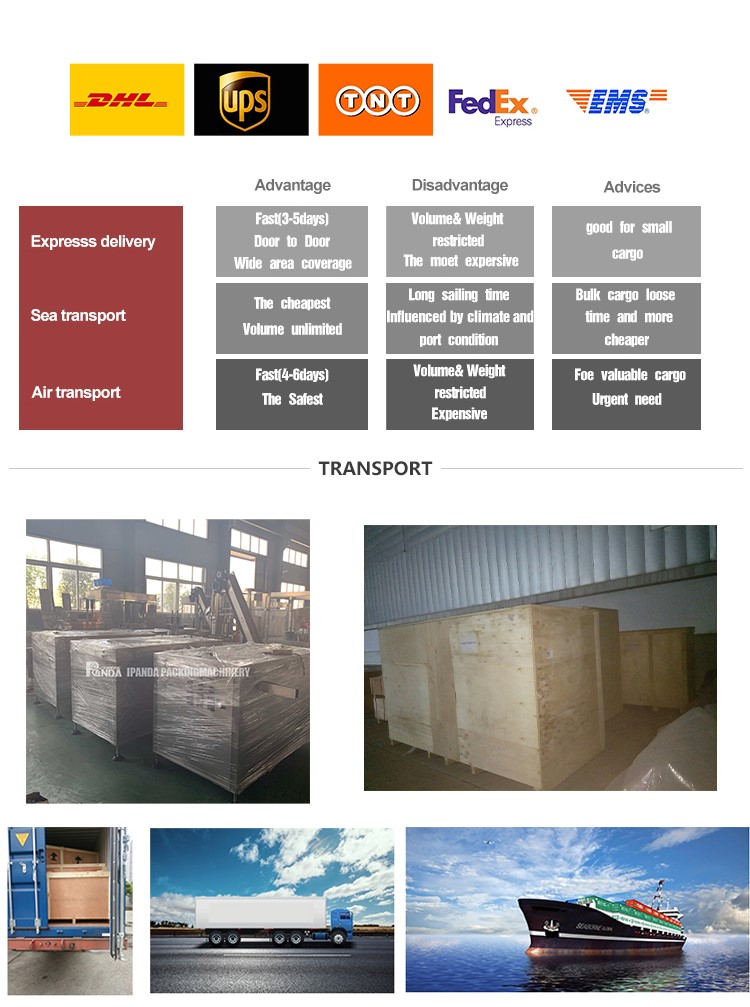

4.Engineers kupezeka kwa utumiki makinakutsidya kwa nyanja